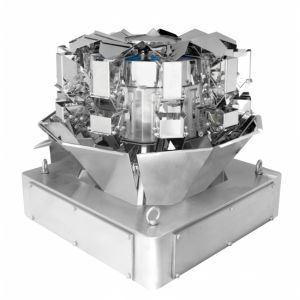

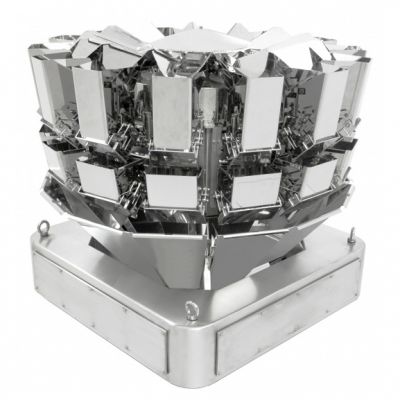

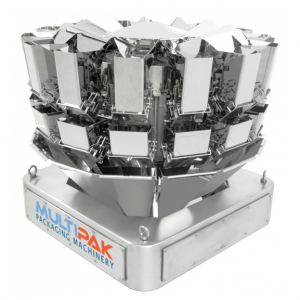

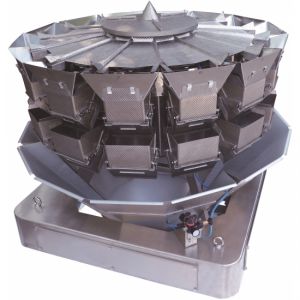

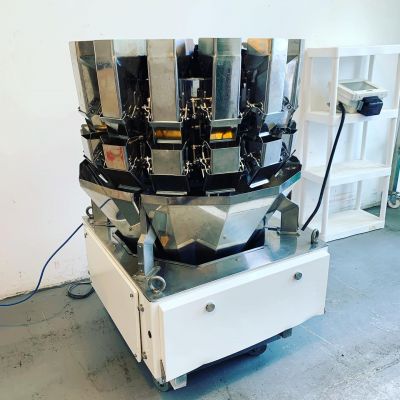

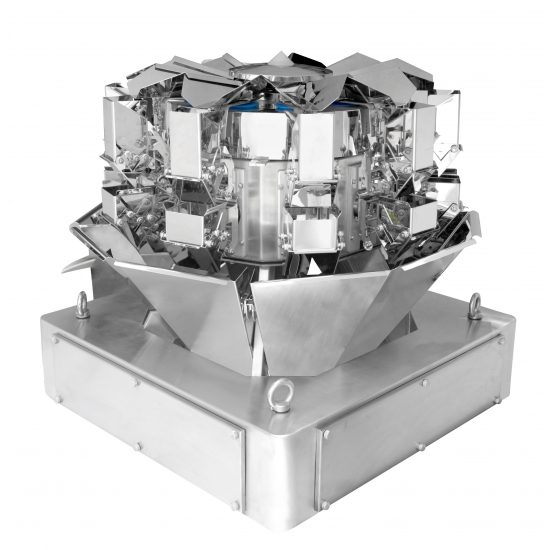

What is a Multihead Weigher?

A multihead weigher or also known as a combination weigher, is a highly efficient and precise weighing machine commonly used in the food packaging industry. It is designed to accurately portion and dispense a wide variety of products, such as granules, powders, snacks, candies, frozen foods, and more.

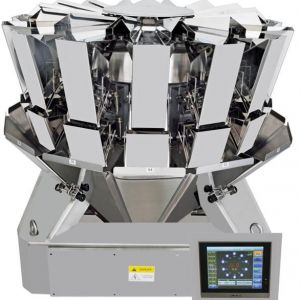

The basic components of a multihead weigher typically include:

-

Hopper: The individual product hoppers are where the bulk product is initially placed. Each weigher head has its own hopper.

-

Weighing Buckets: Below each hopper, there are usually several weighing buckets or pans arranged in a circular configuration. The number of buckets can vary depending on the machine's size and complexity.

-

Load Cells: Each weighing bucket is equipped with a sensitive load cell, which measures the weight of the product placed on it. These load cells are critical for achieving high accuracy during the weighing process.

-

Vibratory Feeders: Vibratory feeders beneath the hoppers are responsible for regulating the flow of product into the weighing buckets. They help ensure a consistent supply of product during the weighing process.

-

Computerized Control System: The multihead weigher is controlled by a sophisticated computer system, which operates the vibratory feeders and analyzes the weight data from each load cell. It calculates the optimal combination of weights from the individual buckets to achieve the desired overall weight for the product.

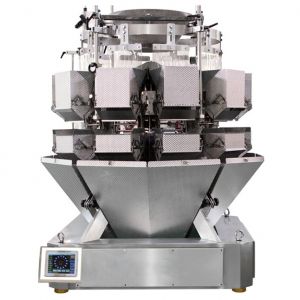

The operation of a multihead weigher involves the following steps:

-

Product Distribution: The product is distributed from the main hopper into individual hoppers, one for each weigher head.

-

Weighing Process: The computerized control system activates the vibratory feeders to release specific amounts of the product into each weighing bucket.

-

Weight Calculation: The load cells measure the weight of the product in each bucket, and the computer processes this data to calculate the best combination of weights to achieve the target weight.

-

Discharge: Once the correct weight combination is determined, the weighed portions are discharged simultaneously from all the buckets into a collection chute or directly into the packaging machine.

The use of multiple weighing heads allows the multihead weigher to achieve high speeds and accuracy, making it a popular choice for large-scale production lines in the food packaging industry. The ability to weigh multiple products at once and quickly adapt to changes in product density and flow helps reduce product giveaway and optimize production efficiency.

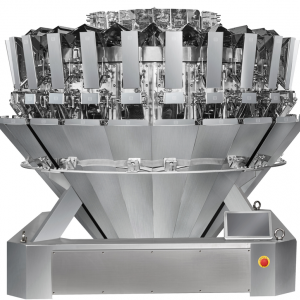

Select a Multihead Weigher Solution